- Forklift

- Home

- Allison Transmission

- Astra

- Avia

- BAW

- BT

- AGCO

- Allis-Chalmers

- Beifang Benchi

- Bobcat

- Case

- Caterpillar

- CESSNA

- Challenger

- Claas

- CLARK

- Crown

- Cummins

- Daewoo

- DAF

- Daihatsu

- Detroit Diesel

- Deutz

- Dodge

- Dongfeng

- Doosan

- Eaton

- FAW

- FENDT

- FiatAgri

- Freightliner

- Ford

- Hangcha

- Hino

- Howo

- Hyundai

- International

- ISUZU

- Iveco

- JAC

- JCB

- John Deere

- jungheinrich

- Kalmar

- Kenworth

- Kia

- KUBOTA

- Komatsu

- Mack

- MAN

- Massey Ferguson

- Mercedes-Benz

- Mitsubishi Truck

- Nissan

- New Holland

- Paccar

- Perkins

- Peterbilt

- Renault

- Scania

- Shaanxi

- Shantui

- Still

- Tata

- TCM

- Terex

- Toyota

- Volvo

- Weichai

- XCMG

- Yale/Hyster

Daewoo Ultra Novus, Forklifts Fault Codes

DIAGNOSTICS OF ENGINES DL06, DL08, DV11

Diagnosis of the engine can be carried out using a diagnostic scanner or by checking the DTCs displayed on the instrument panel by a flashing warning light with

engine image.

We recommend using a diagnostic scanner as it provides a quick and accurate check.

Diagnostic procedure

a) Turn the main battery switch to the "ON" position.

b) The ignition key is in the "ON" position.

c) The engine is not running.

d) Press the engine diagnostics button. (Hold for 2 sec).

e) The control lamp with the engine image will start blinking on the instrument panel.

f) Check the trouble codes, then turn the ignition key to the "OFF" position.

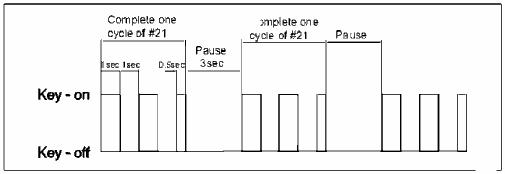

Fault code display

The examples below show how fault codes are displayed with

using the engine indicator light

Clearing a fault code

DTCs stored in the electronic control module (ECM) memory can be easily erased using a scanner.

The history of the corrected codes of malfunctions is deleted automatically from the ECU memory after 5 days.

Clearing the corrected fault codes from the ECU memory can be done manually by turning the ignition on and off 5 times. Do not use this method all the time, as this will affect the search time

service center using a scanner. It will be necessary to reproduce the conditions for the occurrence of malfunctions in the real conditions of engine operation when the vehicle is moving.

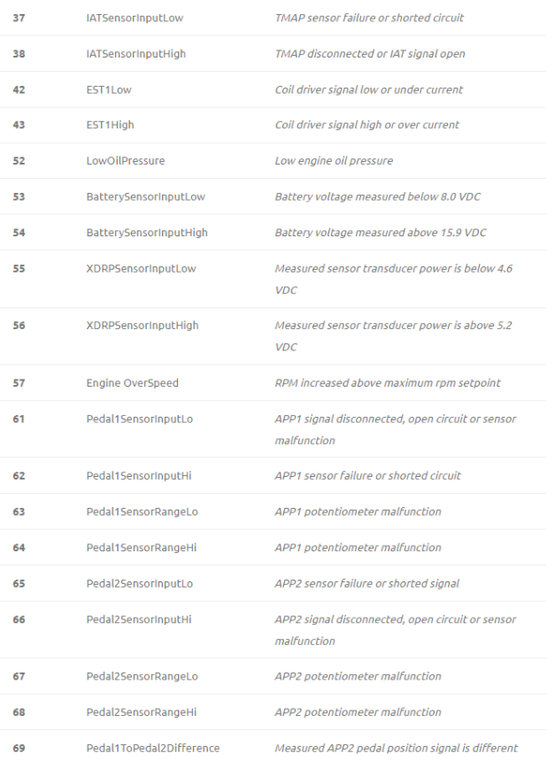

NO . ERROR CODE ( SPN ) FLASH CODE FAULT DAEWOO NOVUS

1 18 2.2 fuel pressure sensor

2 91 2.3 gas pedal (APP1)

3 100 1.8 oil pressure sensor

4 102 1.4 intake air sensor

5 110 1.1 coolant temperature sensor

6 132 2.6 air flow sensor

7 158 2.1 battery VOLT

8 171 1.5 air temperature sensor

9 174 1.2 fuel temperature sensor

10 175 1.7 oil temperature sensor

11 190 4.4 engine speed sensor (speed

12 597 2.8 service brake switch

13 598 2.7 clutch switch

14 602 2.9 Cruise Control

15 606 3.8 engine speed

16 623 8.6 low voltage of the power supply more than 20

17 627 4.8 power supply

18 647 7.2 low voltage of the power supply more than 7

19 723 10.6 engine overspeed

20 734 5.8 Solenoid. Power supply 1 or more

21 735 5.9 Solenoid. Power supply unit 2 or more

22 736 6.1 Solenoid. Power supply 3 or more

23 737 6.2 Solenoid. Power supply 4 or more

24 738 6.3 Solenoid. Power supply 5 or more

25 739 6.4 Solenoid. Power supply unit 6 or more

26 974 9.6 remote throttle

27 975 3.1 MWIS module

28 977 11.6 EBC1 message timeout

29 1072 7.7 under voltage of the power supply more than 12

30 1073 7.9 under voltage of the power supply more than 14

31 1208 3.3 Inlet air pressure control

32 1209 3.4 exhaust gas regulation

33 1213 7.5 under voltage of the power supply unit more than 10

34 1238 3.6 Auto T / M control

35 1320 1.6 air pressure sensor

36 1322 10.4 ignition defects in different cylinders

37 1323 9.7 defective ignition cylinder # 1

38 1324 9.8 defective ignition cylinder # 2

39 1325 9.9 defective ignition cylinder # 3

40 1326 10.1 defective ignition cylinder # 4

41 1327 10.2 defective ignition cylinder # 5

42 1328 10.3 defective ignition cylinder # 6

43 1482 3.5 T / M control

44 1485 3.9 main relay SCG

45 1624 2.5 machine speed

46 1639 11.5 fan speed sensor

47 520193 1.3 intake air temperature sensor

48 520194 1.9 Multiple position switch

49 520195 2.4 gas pedal (APP2)

50 520196 3.2 MPROP fuel pressure control

51 520196 11.7 MPROPHIGH fuel pressure control

52 520197 3.7 CAN - In Line

53 520198 4.1 increased channel shut - off (shutdown)

54 520199 4.2 engine speed sensor ( crankshaft)

55 520200 4 3 Engine speed sensor

56 520201 4.5 EEPROM data storage error in the electronic control unit

57 520202 4.6 activation error after turning on the electronic control unit

58 520203 4.7 PRV check error

59 520204 4.9 malfunction of the main relay SCB

60 520205 5.1 malfunction of the main relay ECM

61 520206 9.1 CAN - ALine

62 520207 5.2 balance cylinder, cylinder 1

63 520256 5.3 balance cylinder, cylinder 2

64 520257 5.4 cylinder balance, cylinder 3

65 520258 5.5 cylinder balance, cylinder 4

66 520259 5.6 cylinder balance, cylinder 5

67 520260 5.7 balance cylinder, cylinder 6

68 520262 6.6 undervoltage of the power supply more than 2

69 520262 8.3 undervoltage of the power supply over 17

70 520263 6.7 undervoltage of unit 3

71 520264 7.3 undervoltage of the power supply more than 8

72 520265 7.4 undervoltage of the power supply more than 9

73 520266 7.8 undervoltage of the power supply unit more than 13

74 520267 7.6 undervoltage of the power supply more than 11

75 520268 6.9 undervoltage of the power supply more than 5

76 520269 6.8 undervoltage of the power supply more than 4

77 520270 8.1 undervoltage of the power supply unit more than 15

78 520271 8.2 undervoltage of the power supply unit more than 16

79 520272 8.4 undervoltage of the power supply more than 18

80 520273 8.5 undervoltage of the power supply more than 19

81 520274 8.7 undervoltage of the power supply more than 21

82 520275 8.8 undervoltage of the power supply unit more than 22

83 520276 8.9 undervoltage of the power supply over 23

84 520277 9.2 undervoltage of the power supply more than 24

85 520278 9.3 undervoltage of the power supply unit more than 25

86 520320 9.4 undervoltage of the power supply more than 26

87 520324 6.5 undervoltage of the power supply unit more than 1

88 520325 7.1 undervoltage of the power supply unit more than 6

89 520326 10.5 the injector was opened too long

90 520327 10.7 gas pedal (ARRZ)

91 520328 10.8 control of smooth ignition Seg -0

92 520329 10.9 control of smooth ignition Seg -1

93 520330 11.1 Smooth ignition control Seg -2

94 520331 11.2 control of smooth ignition Seg -3

95 520332 11.3 Smooth ignition control Seg -4

96 520333 11.4 control of smooth ignition Seg -5

97 520334 11.7 intake air pressure plausibility

98 520335 11.8 intake air temperature plausibility

99 520336 11.9 coolant temperature plausibility

100 520337 12.1 oil temperature plausibility

101 520338 12.2 fuel pressure plausibility

102 520339 12.3 UDV protection - lowest value of "torque"

103 520340 12.4 UDV protection - the highest value of "torque"

104 520341 12.5 DCU

DAEWOO TIER II ENGINE/FUEL SYSTEM FAULT CODES