- Forklift

- Home

- Allison Transmission

- Astra

- Avia

- BAW

- BT

- AGCO

- Allis-Chalmers

- Beifang Benchi

- Bobcat

- Case

- Caterpillar

- CESSNA

- Challenger

- Claas

- CLARK

- Crown

- Cummins

- Daewoo

- DAF

- Daihatsu

- Detroit Diesel

- Deutz

- Dodge

- Dongfeng

- Doosan

- Eaton

- FAW

- FENDT

- FiatAgri

- Freightliner

- Ford

- Hangcha

- Hino

- Howo

- Hyundai

- International

- ISUZU

- Iveco

- JAC

- JCB

- John Deere

- jungheinrich

- Kalmar

- Kenworth

- Kia

- KUBOTA

- Komatsu

- Mack

- MAN

- Massey Ferguson

- Mercedes-Benz

- Mitsubishi Truck

- Nissan

- New Holland

- Paccar

- Perkins

- Peterbilt

- Renault

- Scania

- Shaanxi

- Shantui

- Still

- Tata

- TCM

- Terex

- Toyota

- Volvo

- Weichai

- XCMG

- Yale/Hyster

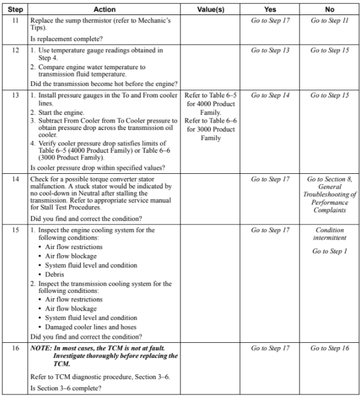

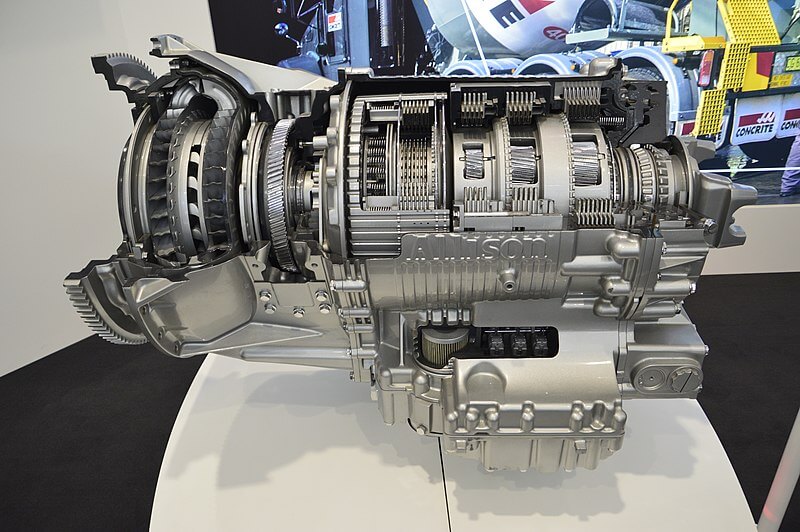

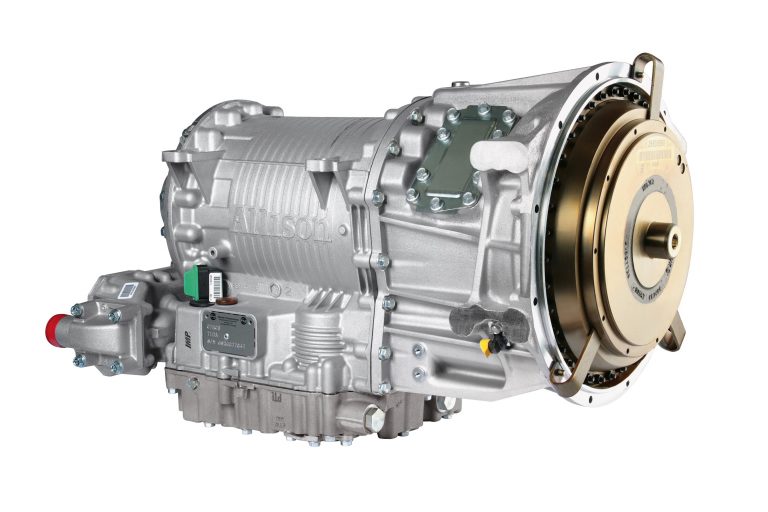

ALLISON TRANSMISSION SERVICE MANUALS. EWD FREE DOWNLOAD

- Type of automatic transmission 3000 Series

- Type of automatic transmission 3000 Series with retarder

- Nameplate of automatic transmission

- Electronic control system

- Operation of automatic transmission

- General operating instructions

- Gear shifting

- Gear selector elements

- Digital display

- Mode button "MODE"

- LED for enabling additional mode

- Menu Button (Toggle Switch Only)

- Mode selection by push-button switch

- Positions of the lever switch

- Other elements of management and control

- Control lamp of malfunctioning "Check Trans"

- Control lamp for automatic transmission oil temperature

- Automatic transmission oil temperature gauge

- Retarder control (optional)

- Battery retarder

- Movement

- The order of gear shifting

- Driving on slopes

- Engine braking

- Retarder braking

- Safety functions

- Protection against motor over-rotation and switching on too low transmission

- Interlocking the inclusion of transmission

- Influence of automatic transmission and retarder oil temperature on gear shift

- Additional functions

- "Fast neutral" for garbage trucks

- Blocking of movement for fire trucks and special equipment

- Speed output

- Measures when towing a vehicle

- Starting the engine by towing

- Towing with the engine off

- Diagnostics of errors

- Reading error codes

Allison 1000-2000 Series Service Manual Download

ALLISON 1000,2000 – Automatic Transmission Service Group Download

Allison 3000 series Service Manual TS3989RU GEN4 Download

Allison AT500 and AT1500 Service Manual PDF Download

Allison HD4060 Service Manual PDF Download

Allison HD4060 Transmission Operator Manual Download

Allison MT(B)600 Series Transmissions Service Manual PDF Download

Allison Transmission MT4015EN Mechanic‘s Tips Download

Allison Transmission – AT, MT, HT Series ON-Highway transmission – PDF manual Download

Allison Transmission 3000 4000 Series Operators Manuals Download

Allison Transmission 4000 B500 Series 4K Technicians Guide PDF Download

Allison Transmission 5000, 6000, 8000, 9000 SeriesOff-Highway Transmissions Commercial Electronic Controls 2 (CEC2) TS3353EN Troubleshooting Manual PDF Download

Allison Transmission DDEC IV Application and Installation Manual Download

Allison Transmission HT, HTB, CLT, CLBT 700 Series Service Manual Download

Allison Transmission RDS Brochure Rugged Duty Series Brochure Sa3743en Download

Allison Transmission Removal Guide Download

Allison Transmission Vocational Model Guide PDF Download

The hydrodynamic modelling of torque converters. Download

Allison Transmission Parts Catalog PDF

Allison Transmission 2011 PDF Parts Catalog Download

Allison Transmission (M74) LCT 1000 2000 2400 Spare Parts Catalog Download

Allison Transmission 5000-6000 Series Parts Catalog Download

Allison Transmission AT540, 543, 545 Parts Catalog Download

Allison Transmission MT643 parts Download

5000 and 6000 Product Families

CLBT 5861*

CLBT 5961*

CLBT 5962*

CLBT 5963*

CLBT 6061*

CLBT 6062*

CLBT 6063*

CLT 5861*

CLT 5961*

CLT 5962*

CLT 5963*

CLT 6061*

CLT 6062*

CLT 6063*

H 5610A(R)*

H 5620A(R)

H 6610A(R)*

H 6620A(R)

M 5600A(R)*

M 5610A(R)*

M 5620A(R)

M 6600A(R)*

M 6610A(R)*

M 6620A(R)

S 5600H(R)*

S 5600M(R)*

S 5610A*

S 5610H(R)*

S 5610M(R)*

S 5620AR

S 5620H(R)

S 5620M

S 6600AR*

S 6600H(R)*

S 6600M(R)*

S 6610A*

S 6610H(R)*

S 6610M(R)*

S 6620A

S 6620H(R)

S 6620M

VCLBT 5861*

VCLBT 5961*

VCLBT 6061*

VCLT 5861*

VCLT 5961*

Allison Transmission Fault Codes PDF

Allison 1000 and 2000 Product Families Troubleshooting Manual Download

Allison 1000 and 2000 Series Error codes List Download

Allison 1000,2000 series error code list Download

Allison DOC 7.0 PC Service Tools – User Guide PDF Download

Allison Electronic Controls Troubleshooting Manual Download

Allison TROUBLESHOOTING Codes Manual PDF Download

Allison 3000-4000 Series Troubleshooting Manual Download

Allison – Shift Selector – Operator and Diagnostic Trouble Code manual Download

Allison 3000,4000 series error code list Download

Allison 30004000 series error code list – download PDF manual Download

Allison Troubleshooting Manual GEN4 Download

Allison TS2973EN Troubleshooting Manual PDF Download

Shift Selector – Operator and Diagnostic Trouble Code manual Download

How often should an Allison transmission be serviced?

Salesman. Severe driving conditions are classified as HD by Allison such as buses, large trucks, etc. Every 50K For most fluids, unless you are using Castrol Transynd or AMSOIL Torque Drive and manually flush the transmission. Then the replacement interval is 150 km.

Resetting the Allison Transmission Service Indicator Light

To reset the service indicator light.

Turn on the key, do not start the engine.

Move the gear selector to the NDNDNRN position, pausing briefly (less than 3 seconds) between each shift.

MAXIMUM COOLER FLOW AT MINIMUM PRESSURE DROP

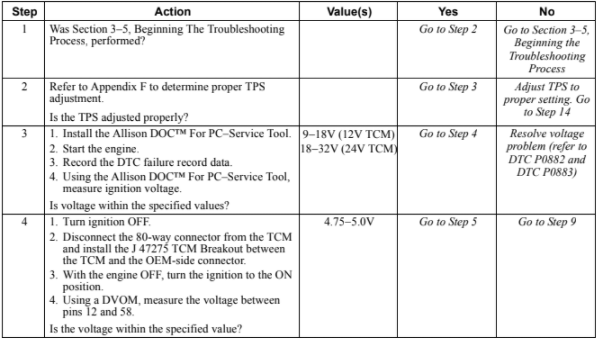

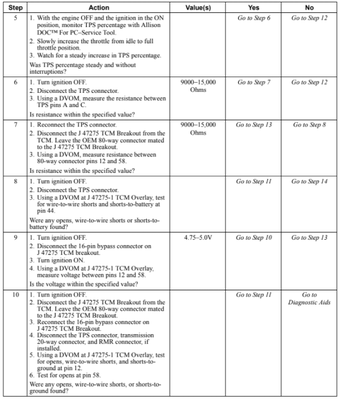

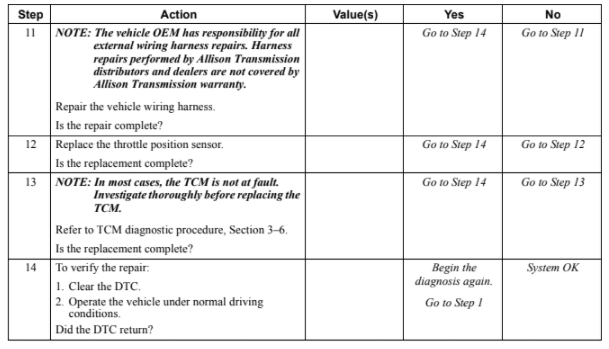

DTC P0123 Pedal Position Sensor High Voltage

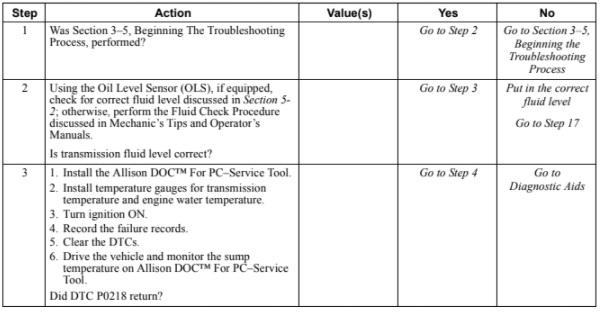

DTC P0218 Transmission Fluid Over-Temperature

DTC P0218 Transmission Fluid Over-Temperature

DTC P0562 System Voltage—Low

DTC P0614 Torque Control Data Mismatch—ECM/TCM

DTC P0634 TCM Internal Temperature Too High

DTC P063E Auto Configuration Throttle Input Not Present

Model M5620 six forward and two reverse gears

Yes: electronic control system, remote control. Self-diagnosis. The chassis drive is mechanical switchable.

Options: transfer case, up to two power take-offs (manual electronic control), hydraulic retarder, Applicable: to drive the chassis of off-road vehicles (mining dump trucks, mobile drilling rigs, mobile pumping units, etc.)

Model S5620 Six forward and one reverse (2nd reverse manual)

Yes: electronic and mechanical control systems

Options: up to two power take-offs (manual electronic control), Applications: usually used to drive stationary equipment (drilling pumping units, drilling equipment, cementing pumps, etc.)

Model H5620 six forward gears and one reverse gear

Yes: electronic control system

Options: up to two power take-offs (manual electronic control), hydraulic retarder, Applications: Mainly applied to drive lifting equipment (winches, offshore winches, etc.)

AVTEC 8000, AH8700 series is a fully automatic Powershift transmission with 7 forward and 1 reverse speeds and electronically controlled. This transmission is available with an engine driven PTO that can be mounted directly to the machine or remotely using a linear arrangement and a hydrodynamic retarder.

Buy Buy

AVTEC 754 transmission series

AVTEC 750 Series transmission is an automatic transmission that has 5 forward and 1 reverse speeds with an integrated output.

This transmission is also available with a drop option with optional hydrodynamic retarder, engine driven PTO and converter driven PTO. This equipment can be installed both directly on the unit and remotely.

The 6600 series transmissions have 6 forward and 2 reverse speeds and can be equipped with hydraulic manual, electric manual and fully automatic controls.

This transmission is available with an engine driven PTO that can be mounted directly to the machine or remotely using a linear, chaotic arrangement and hydrodynamic retarder.

Model M6620 six forward and two reverse gears

Yes: electronic control system, remote control. Self-diagnosis. The chassis drive is mechanical switchable.

Options: transfer case, up to two power take-offs (manual electronic control), hydraulic retarder, Applied: to drive the chassis of off-road vehicles (mining dump trucks, mobile drilling rigs, mobile pumping units, etc.).

Model S6620 Six forward and one reverse (2nd reverse manual)

Yes: electronic and mechanical control systems

Options: up to two power take-offs (manual electronic control), Applications: usually used to drive stationary equipment (drilling pumping units, drilling equipment, cementing pumps, etc.)

Model H6620 six forward gears and one reverse gear

Yes: electronic control system

Options: up to two power take-offs (manual electronic control), hydraulic retarder, Applications: Mainly applied to drive lifting equipment (winches, offshore winches, etc.)